Great attention must be paid to cleanliness when laying fiber optic cables. The end faces of the fibers have to remain free of grease and dust. R&M lets installers in on a simple rule for cleaning optical fibers: Test first, then clean if necessary, then plug it in.

Dirt can prove fatal

Optical fibers will soon be in every household. Lots of installation companies are thus now familiarizing themselves with professional handling. The most important thing is great care. Cables and particularly the fibers themselves should be kept clean and handled gently. The constant increase of data rates is making transmission quality more sensitive to dirty connections – even with multimode!

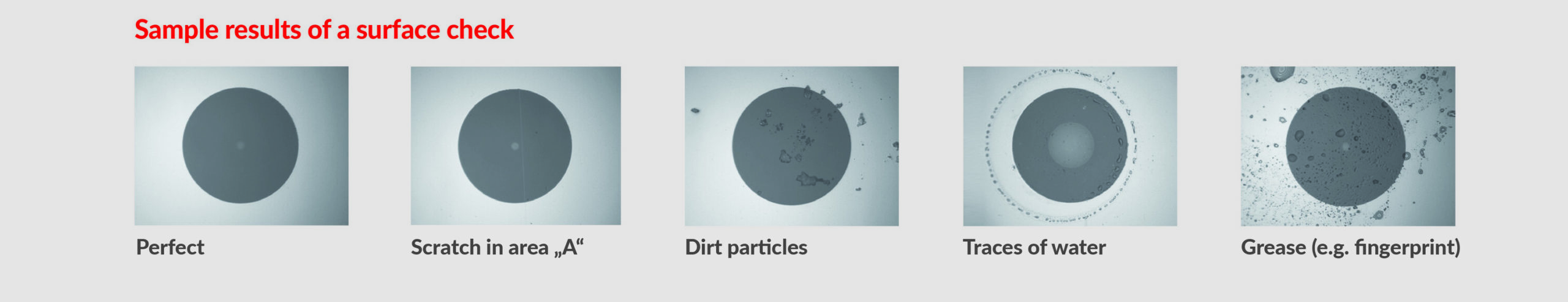

The performance of a fiber optic system depends heavily on how clean the interfaces are. Dirt particles, grease, dust, etc. can have a highly negative impact on the transmission characteristics. They can actually destroy a fiber optic connection depending on the circumstances. The connector can “burn” as they say in the trade.

If the connector is plugged in without first being tested, it could well be too late. The high pressure in the connection means that particles are immediately pressed in and this causes irreversible damage.

This is why it is becoming increasingly important to test all connectors and adapters, and, if necessary, to clean them before they are mated – even new products that have just come out of the packing.

Good goods are always clean

Most connectors actually arrive at their place of deployment in the pristine state in which they left the production facility of conscientious manufacturers such as R&M. In such cases, the installer can actually only make the quality worse by cleaning the connector.

This is why R&M recommends this simple rule: Always test first, then clean if necessary, then plug it in. For this reason, a microscope or a similar test tool should always be available when carrying out installation work.

This article appeared originally on R&M’s blog.