Beginning with the end in mind is often the key to success. So when preparing to upgrade or build a new campus backbone, the same mindset should apply. The digitization of everything is creating opportunities for businesses to create more value from the network infrastructure. Smart organizations are now placing the network infrastructure front and center in the planning process because it is crucial the network is set up to scale with the applications needed today and tomorrow without major and expensive add-ons. Measure twice, cut once, is the saying. For example, is your customer ready for advanced applications using WiFi, small cells, cameras, and more?

Preparing for events on the horizon such as smart buildings and the reliance on cloud applications needs to be considered, but what about the applications and technologies that are not planned? That’s where good planning can help you make best key strategic decisions for your next project.

Whether you are planning a college campus or a Fortune 500 business-park network, don’t let your structured cabling infrastructure be the limiting factor. The goal of this article is to help you think about some products and services at a high level so you are prepared to discuss with your stakeholders. Let’s consider several areas of the campus network where you should consider options: cabling, pathways, hardware, connectivity, and services.

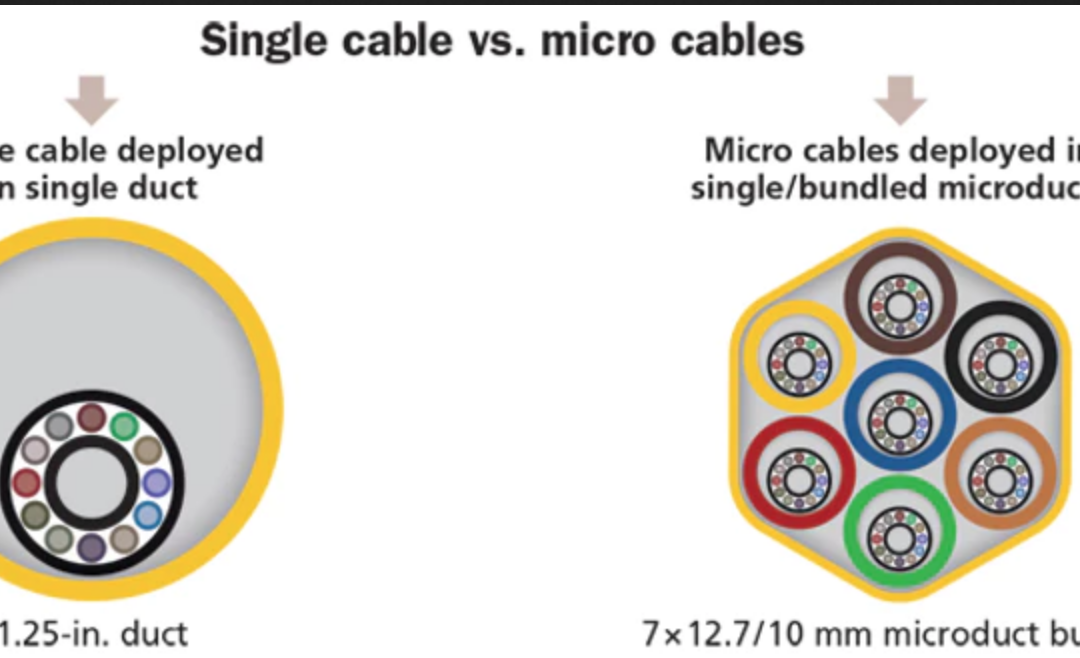

Comparison of a single cable deployed in a single duct, to micro cables installed in a 7-way duct.

Cabling and pathway

One of the first things that comes to mind when planning a new network or an upgrade to an existing network is how the cable will get from point A to point B. The cable pathway is one of the biggest challenges during the planning and installation stages of the project.

Microducts can be an excellent way to efficiently utilize the space within an existing duct. They are usually bound together with an oversheath into a bundle and sub-divide existing duct into smaller ducts for micro cables. The microducts themselves range in outer diameter/inner diameter as they are measured, from 22/16 (mm) down to 5/3.5 (mm) with bundle sizes varying. Micro cables are optimized for microducts and can be installed either by pulling, jetting, or blowing. They generally are loose tube and have either 250- or 200-micron fibers.

Combining microduct and micro cable offers several advantages over conventional options. Some, but not all, of the advantages will be covered here. For example, higher fiber densities can be achieved in a given duct size. Additionally, lower deployment costs and duct capacity can be more efficiently used in the future compared with conventional cable and duct.

All micro cables are not created equal. Cable access can be time-consuming and is not without risk. Some micro cables have advanced features that have eliminated the binders and yarns that slow down access to the buffer tubes. Consider micro cables that do not require sharp “hook” blades commonly used for accessing cables, but rather require something easier and safer like a pair of pliers.

Outside of microducts and micro cable, an additional and relatively new option is composite cable. Composite cables contain optical fiber for carrying data and copper conductors for carrying power. These types of cables can be employed in outdoor and indoor environments where remote power and communications is needed.

The key is the ability to provide maximum flexibility in terms of distance, bandwidth, and power capabilities that can take fiber and power all the way from the campus backbone into the horizontal to provide power and communications directly to switches and/or devices. This allows for networks to be freed from the 100-meter distance/power limitation associated with traditional networks. The performance of composite cable exceeds traditional copper network cable in terms of distance, bandwidth, and power at 100 meters and beyond.

The use of composite cable and associated remote power sources for centralizing cable runs provides the ability to run power and communications out to devices thousands of feet away. This all depends on what the powered device requires in watts and the distance to determine what AWG copper conductor size is needed. Composite cable could be a fit anywhere the limitation of category cableisevident. Look for vendors that make it easy to deploy composite cables with reel-in-box-type products that eliminate the need for jack stands,for example.

Hardware

Now we will move on from cable and pathways to where the cable must land. Hardware provides a place to house terminations, organize, and protect exposed fiber. While thinking about a new network install or network upgrade, you should think about what hardware options are available in the outside plant and the inside plant to position your customers for easy future moves, adds, and changes (MAC).

Thinking strategically, does the vendor have product available at distribution, are the components compatible across a broad set of hardware products, and is the hardware easy to install and conduct MAC work? Is the hardware equipped to provide options for both mechanical and fusion splicing? How easy is it to strain-relieve cable, label the housing, and route fiber within the housing? Is the hardware compatible with pigtailed splice cassettes that come with panel, pigtail (routed, color-coded, and stripped to 250 micron), heat shrinks, and cassette under one part number? Another example would be to make sure the hardware comes standard with components such as strain-relief brackets and blank panels, and also comes assembled and is ready to go out of the box. No one wants to assemble hardware on the Jobsite.

This illustration compares the fiber density of a standard loose-tube fiber in a standard duct (left), MiniXtend cables in microduct (middle), and MiniXtend HD cables in microduct (right).

Outside plant hardware

If placing hardware in an outdoor environment, consider NEMA or IP-rated closures. NEMA stands for National Electrical Manufacturers Association; it defines standards used in North America to describe hardware that prevents the ingress of environmental hazards. IP, or International Protection Marking, published by the International Electrotechnical Commission (IEC), is a classification system describing how things are protected against the ingress of foreign objects and water. If housings are potentially being exposed in some way to environmental materials, NEMA and/or IP rating should be considered. The tables briefly describe the variousclassifications.

Consider where you will place your OSP closures: wall mount, pole mount, or below grade in a vault or manhole. Other things to consider are the fiber capacity, splice cassette capability, and the ability to lock the housing. NEMA/IP-rated hardware also works well in environments where rodents or animals are aconcern.

Small-form-factor hardware

There are cases in which small-form-factor hardware is needed—something that can fit in the palm of your hand and is less than 24 optical fibers. For example, outdoor pole-mounted cameras are typically far away from the switch gear in a closet, and in some cases a media converter or switch must be collocated with the camera. Optical connectivity is also needed to provide communication back to the access switch inabuilding.

Often, the NEMA/IP-rated enclosure used for housing the electronics does not have fiber patching available. Small-form-factor optical hardware can then be placed in the enclosure. As you consider a wide range of applications in outdoor environments, think about the range of small-form-factor housings available fromthevendor.

The image on the left depicts the advanced stripping process that starts with commonly used hand tools to initiative the jacket peel. The image on the right shows the installer simply pulling apart the cable jacket to the required stripping length.

Closures

Typically, direct-buried closures are placed in manholes or vaults and must be sealed because of the likelihood of the closures being submerged in water. There are several factors to consider when choosing the correct closure.

- What type of ingress protection is offered (for example, IP68 and/or GR771)?

- Think about what fiber capacity is needed day 1 and what is likely to be needed for the expansion of the network.

- How much slack storage isneeded?

- Can microduct be brought directly into the closure?

- Does the closure have the correct grommets for the incoming cables?

- What type of strain relief is available and is it compatible with the incoming cable?

- Can the closure be expanded overtime?

These are just a few of the considerations for closures.

Inside plant hardware

When considering hardware that will be located inside a building, there are several things to consider. Is there room for a 48U rack, or is wall space the only thing available? If the room is going to be the main telecom room for the building, you should opt for a rack-mountable housing that provides the most capacity for future expansion.

In some cases, a wall- or surface-mount box may be your only option in small telecom closets where the room also acts as a storage area. If wall- and rack-mountable options are not available, consider the ceiling or utilizing a raised floor if available.

Is there a concern regarding dust and/or rodents? If that is the case, a NEMA/IP enclosure should be considered. If space constraints are a top concern, seek out the vendor’s small-form-factor housings.

Shown here is an illustration of a composite cable, containing optical fiber for carrying data and copper conductors for carrying power. Composite cables can be employed in outdoor and indoor environments where remote power and communications are needed.

Connectivity

Now that we have discussed pathway/cabling and hardware, we will move on to what connectivity options to consider. Ultimately, a big consideration for the contractor is how the cable will be terminated. Sometimes this is specified by the end-user and sometimes it is at the contractor’s discretion.

If there is no customer specification, many factors can influence the termination choice. These factors can include: cable type, e.g. if loose tube or tight-buffered fiber; fiber counts; are the crews doing the work equipped with mechanical or fusion splicing technologies; what material is currently available at distribution?

How well trained are the technicians with a given termination type? Better-trained technicians equal better constancy and the reduction of costly and time-consuming rework of terminations that fail to pass certification tests.

Consider vendors who not only offer a full range of termination choices and hardware products that make this easy to accomplish, but also with the ability to provide in-person training asnecessary.

Services

The services a vendor offers can sometimes go unnoticed until a key moment of need. Like the mortar between the bricks, services help prevent things from falling through the cracks.

This can happen in the planning, installation, and post-install stages of a project.

Here are some questions you should be askingyourself.

- How well does the vendor support its products?

- Is technical support, from people who understand the product, available via phone?

- If there is a problem on-site, can the vendor deploy someone to the site to help resolve the problem quickly?

- In the planning stages, does the vendor offer free design assistance and product consultation?

- Is training available via webinar or in person?

- Are there tools available to create bills-of-materials and find specification sheets easily?

Having the services and support when and where you need them is critical to keeping the project on track by staying on time and within budget.

Making sure the customer’s campus infrastructure is future-ready is key in being able to utilize new applications and technologies. The consequences of being left behind usually mean you will be playing catch-up, which is an expensive and time-consuming effort.

Partnering with a vendor that always has their eye on the future and introduces innovative products and services is something to consider. Ensuring that the correct cabling and pathways, hardware, and connectivity products are chosen will set a strong foundation and allow the network to scale.

The connected campus combines the elements discussed in this article: cabling, pathways, hardware for inside and outside plant, closures, and connectivity.

Consider a vendor whose products are on the shelf at distribution for those projects and MAC work that suddenly come up. Consider a vendor who takes a solutions approach to enable seamless network scalability by offering a full product set.

Consider a vendor whose products are compatible and easy to use, thus saving time and effort during the install and post-install period.

Remember, the often-overlooked services that a vendor provides can mean the diference between success or failure of a project, to stay within budget and on time. In the end, you often get what you pay for.

Matthew Miller is enterprise market development manager with the Optical Communications business of Corning Incorporated. Corning Optical Communications makes engineers available to demonstrate and support the systems and solutions it provides. Information is available at www.corning.com.

This article first appeared in Cabling Installation & Maintenance.